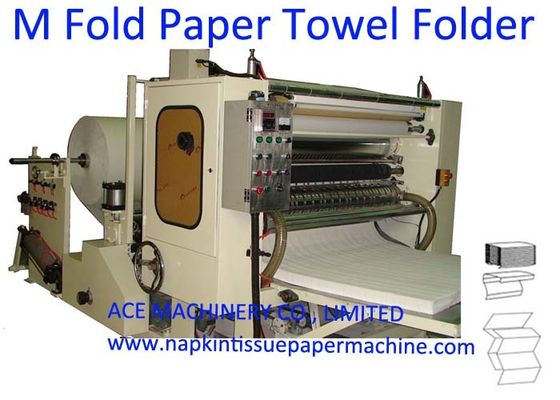

Automatic Paper Towel Machine For The Production Of M-Fold Towels Four Folds

Application

This ACE-M240-6L Automatic Paper Towel Machine For The Production Of M-Fold Towels Four Folds is with steel to steel embossing unit and lamination system. It is good quality high speed tissue converting machine to manufacture M fold interfolded paper towels, four folds paper towels, five folds paper towels, six folds paper towels and nonwoven airlaid tissue, and MG paper napkins etc. It is with the out-of-date latest technology in tissue paper converting. It adopts vacuum folding style. The mainly function of this machine is to manufacture commercial tissue paper products and away-from-home tissue paper products, easy-to-take one by one plain, embossed and LOGO printed and colored and laminated interfolded M W fold paper hand towels. It is an ideal equipment to manufacture high grade away-from-home customized embossed facial tissue paper napkin products.

Advantage:

1 Machine for M fold paper hand towels

2 With glue lamination unit.

3 high speed up to 6000 sheet/min

4 Energy-saving.

5 Vacuum fold

6 Fold stype: M fold, Four fold, Five fold, Six fold.

Quick details:

1 Cylinder cutoff size: 240mm or customized etc.

2 Lamination system.

3 with 6lanes

4 Interfolded and M fold

5 Can connect to logsaw cutting machine

Technical parameters as below

| Model |

ACE-M240-6L |

| Output type |

Automatic Paper Towel Machine For The Production Of M-Fold Towels Four Folds |

| Folding speed |

1000 piece/min/lane * 6lanes = 6000 sheet/min, depending on the paper quality and napkin size. |

| Raw paper |

13-20g/m2 2-ply, 16-45g/m2 1-ply, wooden pulp paper or MG paper or nonwoven airlaid.

Other sizes please specify.

|

| Jumbo roll size |

≤ 1200mm x Φ1200mm (Depends on your napkin size, customized) |

| Napkin size |

Open size: 240±2mm x 200mm Other size, please specify.

Folded size: 80±2mm x 200mm

Fixed cutoff cylinder size is 240m. Other size available, please specify. or Customized.

|

| Folding type |

Inter folding

Vacuum fold

W M fold, Four fold, Five fold, Six fold, 4 folds, 5 folds, 6 folds

|

| Embossing unit |

1- Steel to steel.

2- Embossing pattern can be any LOGO, brand name, flowers etc.

3- Embossing pattern can be customized by client or recommended by us

4- Controlled by screws, mechanical pressing type. Cylinder type is optional.

|

| Point to point Lamination system |

a. With 2 complete sets of point to point lamination units.

b. The whole design is copied Italy design.

c. Heavy chrome coating roll

d. Micro-adjustment of nips between the steel roll

e. Anilox roll for glue applicant.

f. Controlled by cylinders

g. Each lamination unit controlled by an independent reducer. When the machine stops, the motor will start running to rotate the anilox roll to prevent it getting dry.

|

| Tension control |

Speedless Tension control unit to fit the machine for paper of different quaity and different gsm.

With automatic web guiding system.

With automatic web tension control system.

|

| Videos and photos available. |

E. Full Embossing unit (New technology copied Italy)

a. With NEW Technology steel-to-rubber full embossing unit. (Embossing pattern provided by the buyer or recommended by us.)

b. Controlled by level-type pneumatic system copied Italy design. Most other companies’ machines embossing units are controlled by screws or direct-pressing cylinders which make it very difficult to control the web tension and the paper will stick to the rollers, if you are not experienced enough, it will be big problem for you. They mostly put the embossing units on the steel frame, when the machine is running at high speed; it will definitely vibrate very much.

c. Embossing tension is adjustable.(Micro adjustment.) so that the machine can work with papers with different quality and different gsm.

d. Floor standing wallboard structure (thickened full steel plate support structure); to make sure the machine will NOT vibrate when running at high speed. Other companies adopt half steel frame for upper part and half steel part for lower parts, which is weak structure.

Finished products of this Automatic Paper Towel Machine For The Production Of M-Fold Towels Four Folds:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!